For thousands of years, wood has been used for construction, and for making tools, weapons, and furniture. Most simply described, wood is the structural tissue found in the stems and roots of trees. And as you can imagine, not every wood is the same. Some types of wood are more suitable for construction than others, depending on their physical properties—which include density, texture, strength, hardness, stiffness, moisture content, potential for shrinkage, deformation, splitting, and flammability.

There are two primary types of wood—hardwood and softwood—and both are used in different types of construction projects. The basic difference between the two classifications is not in their actual hardness. Hardwood and softwood are distinguished in terms of their reproduction: hardwood comes from deciduous trees, which produces seeds with a covering (think walnut, maple and oak); while softwood comes from gymnosperm trees, which have needles and produce cones (think conifers such as spruce and pine).

How is wood density measured?

Wood density measures the amount of actual wood material in a unit volume of wood. The way we reach that measurement is to calculate the ratio between an oven-dry or air-dried mass of wood (that is, the lightest it will ever get) divided by the green volume of the wood (when it’s freshly cut and has its largest possible water volume) to find its moisture content.

The density of wood differs depending on tree species and tree growth environment. Even the parts of the tree have different densities: branches usually have a lower wood density compared to the trunk.

Wood density and specific gravity

“Wood density” and “specific gravity” are terms that are often used interchangeably, although they are slightly different concepts. Specific gravity is a measurement that uses the density of water (expressed as a baseline of 1.00) as a way to express the ratio of a wood’s density as compared to water. Professional builder and craftsman Jordan Smith explains:

“‘Specific Gravity’ is a shorthand way of saying how dense a material is as compared to water. Technically specific gravity is the measure of a wood’s density as compared to water. If wood were the same density as water, the specific gravity would be 1.00. If it’s less than one—and most wood is less than one—then it’s going to float.”

Learn all about the properties of wood and how wood is used in construction in the MT Copeland course on Wood Materials. Taught by professional builder Jordan Smith, the course covers topics that range from wood hardness and shear strength to joists and laminated veneer lumber.

Density and strength

In order to calculate a wood’s bending strength, we have to determine a measurement called the “Modulus of Rupture,” frequently abbreviated as MOR. Essentially, it is the measure of the strength of a piece of wood loaded with a block perpendicular to the grain until it breaks. Both MOR and compressive strength are measured in pounds per inch.

For thousands of years, wood has been used for construction, and for making tools, weapons, and furniture. Most simply described, wood is the structural tissue found in the stems and roots of trees. And as you can imagine, not every wood is the same. Some types of wood are more suitable for construction than others, depending on their physical properties—which include density, texture, strength, hardness, stiffness, moisture content, potential for shrinkage, deformation, splitting, and flammability.

There are two primary types of wood—hardwood and softwood—and both are used in different types of construction projects. The basic difference between the two classifications is not in their actual hardness. Hardwood and softwood are distinguished in terms of their reproduction: hardwood comes from deciduous trees, which produces seeds with a covering (think walnut, maple and oak); while softwood comes from gymnosperm trees, which have needles and produce cones (think conifers such as spruce and pine).

How is wood density measured?

Wood density measures the amount of actual wood material in a unit volume of wood. The way we reach that measurement is to calculate the ratio between an oven-dry or air-dried mass of wood (that is, the lightest it will ever get) divided by the green volume of the wood (when it’s freshly cut and has its largest possible water volume) to find its moisture content.

The density of wood differs depending on tree species and tree growth environment. Even the parts of the tree have different densities: branches usually have a lower wood density compared to the trunk.

Wood density and specific gravity

“Wood density” and “specific gravity” are terms that are often used interchangeably, although they are slightly different concepts. Specific gravity is a measurement that uses the density of water (expressed as a baseline of 1.00) as a way to express the ratio of a wood’s density as compared to water. Professional builder and craftsman Jordan Smith explains:

“‘Specific Gravity’ is a shorthand way of saying how dense a material is as compared to water. Technically specific gravity is the measure of a wood’s density as compared to water. If wood were the same density as water, the specific gravity would be 1.00. If it’s less than one—and most wood is less than one—then it’s going to float.”

Learn all about the properties of wood and how wood is used in construction in the MT Copeland course on Wood Materials. Taught by professional builder Jordan Smith, the course covers topics that range from wood hardness and shear strength to joists and laminated veneer lumber.

Density and strength

In order to calculate a wood’s bending strength, we have to determine a measurement called the “Modulus of Rupture,” frequently abbreviated as MOR. Essentially, it is the measure of the strength of a piece of wood loaded with a block perpendicular to the grain until it breaks. Both MOR and compressive strength are measured in pounds per inch.

Jordan suggests thinking of a piece of wood marked with two points. “Press on the wood until it breaks,” Jordan says. “The point at which it snaps is the modulus of rupture, or the measure of the amount of weight you can place on a piece of wood before it breaks. The stronger the wood, the higher the MOR number, and the more weight it takes before it ruptures.” Builders take this number into account when considering the strength of woods for different projects.

Density and fasteners

A wood’s density or specific gravity also affects how it holds a fastener. The more dense the fiber—the more fiber that we have per unit area—the more bite that wood will have on a friction based fastener like a nail. But denser woods are also more likely to split if a large fastener is driven into them. Less dense woods—with fewer fibers to be pushed apart by a large fastener—will not hold a small nail as tightly, but they’re less likely to snap if a large fastener is driven into them.

What are the densest woods—and the least dense?

The top three woods by density are:

- Black Ironwood: A rare wood with a density as high as 1.42 g/cm3 (88 lbs. per cubic foot)

- Itin: a small South American tree related to mesquite: .98 g/cm3 (61 lbs. per cubic foot)

- African Blackwood: Considered by some to be the original ebony: 1.08 g/cm3 (67 lbs. per cubic foot)

The least dense woods are:

- Balsa: With cells full of water, balsa lumber is very soft and light, with a density of only 0.11 gm g/cm3 (around 7 lbs. per cubic foot)

- Bamboo: An evergreen perennial, technically a grass: .38 – .85 g/cm3 (23.72 – 53 pounds per cubic foot)

- Basswood: Also known as a linden or tillia, it’s well-known as a light, low-density choice for woodworkers: .32 g/cm3 (20 pounds per cubic foot)

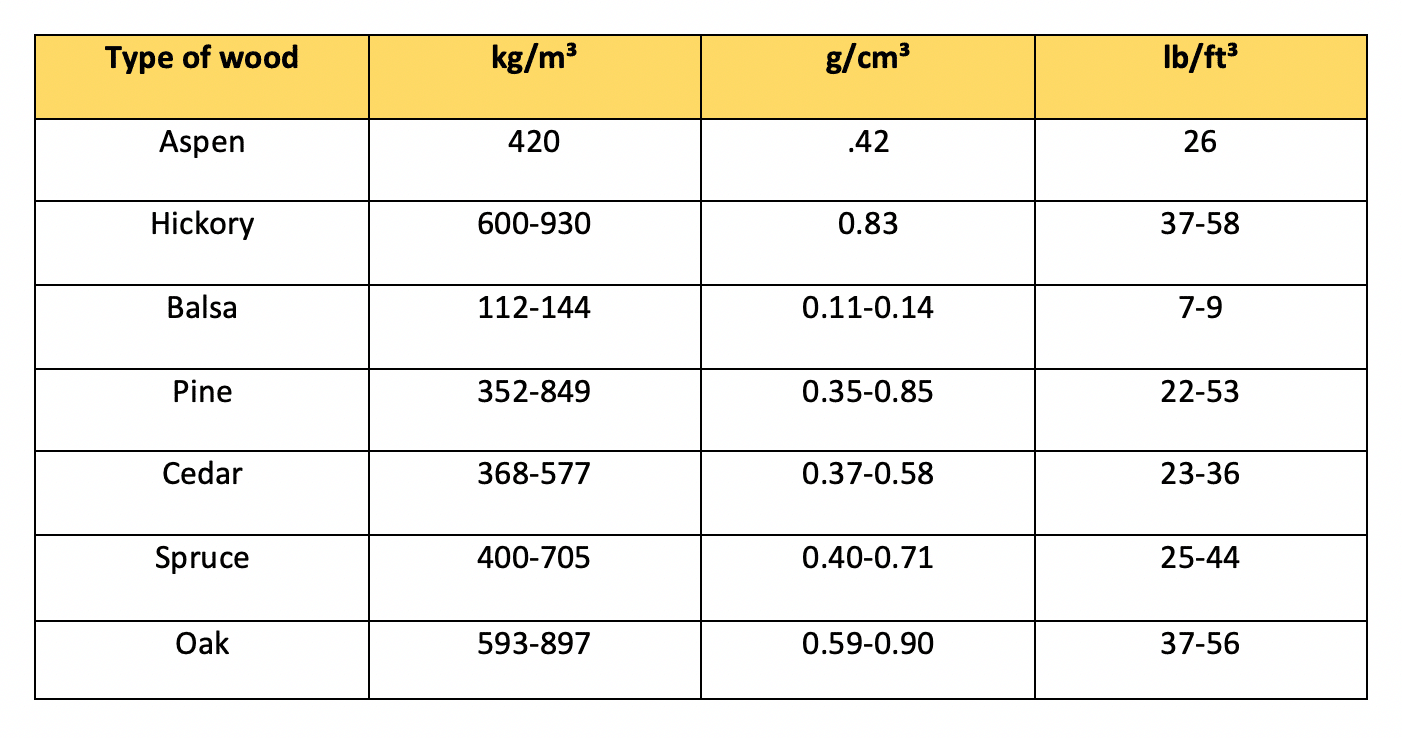

Commonly used woods and their densities

Density is expressed in the units of mass divided by volume, such as grams per centimeters cubed (g/cm3), kilograms per meter cubed (kg/m3), or pounds per cubic foot (lb/ft3). The higher the number, the more dense the wood.

MT Copeland offers video-based online classes that give you a foundation in construction fundamentals with real-world applications. Classes include professionally produced videos taught by practicing craftspeople, and supplementary downloads like quizzes, blueprints, and other materials to help you master the skills.